CHOOSE THE RIGHT MATERIAL

● Steel: heavier, but more durable with a lower price

● Aluminum: lighter, but won’t last as along and more expensive

● Hybrid: combines both steel and aluminum components to get the best of both world

CHOOSE THE RIGHT CAPACITY

● Find your gross vehicle weight and front and rear weights on the sticker inside your door or in your vehicle’s manual

● Be sure to get more weight lifting capacity than you need

● Don’t go overboard – the higher the capacity, the slower and heavier the jack

THE BEST FLOOR JACK: MATERIAL TYPE

Steel

Steel jacks are by far the most popular because they are the least expensive and most durable. The trade-off is weight: they are also the heaviest.

The Pros who opt for steel jacks typically work in repair shops and dealers’ service bays. They perform mostly tire changes and they don’t have to move the jacks too far.

Aluminum

On the spectrums’ other end sits aluminum jacks. These are the most expensive and least durable – but can be less than half the weight of their steel counterparts.

Aluminum jacks are ideal for mobile mechanics, roadside assistance, DIYers, and at the race track where speed and mobility is a priority above all else. In Bob’s experience, some roadside assistance Pros don’t expect aluminum jacks to last more than 3-4 months before it needs a replacement.

Hybrid

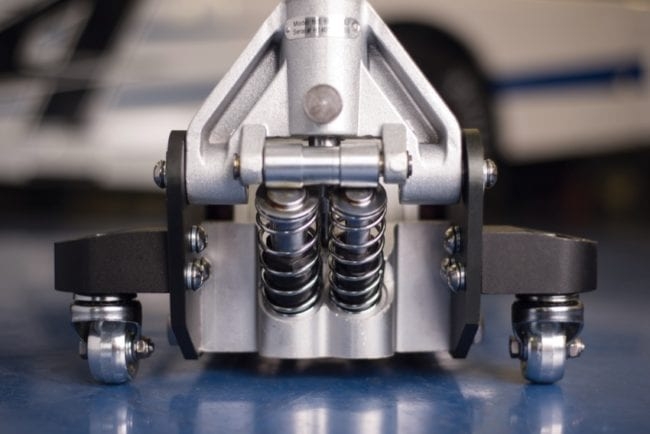

Manufacturers introduced hybrid jacks of aluminum and steel a couple of years ago. The important structural components like the lift arms and power units remain steel while the side plates are aluminum. Unsurprisingly, these hybrids strike a balance in both weight and price.

Hybrids can certainly work for mobile Pro use, but the heaviest day-to-day users are still going to stick with steel for its longer durability. Serious DIYers and gearheads looking to get some weight savings like this option as well.

THE BEST FLOOR JACK: TONNAGE CAPACITY

1.5-ton steel jacks are taking a backseat in popularity to heavier-duty 3- or 4-ton versions. But do you really need that much capacity?

Most Pro users can get away with 2.5-ton machines, but repair shops usually opt for at least 3 tons to cover all the bases.

The tradeoff with a higher capacity jack is slower action and heavier weight. To counter this, many Pro-level jacks feature a double pump piston system that lifts on both upstroke and downstroke only until the jack is under load. At that point, the jack bypasses one of the pumps and the speed returns to normal.

Determine the appropriate tonnage capacity for your vehicle by locating the Gross Vehicle Weight (GVW) on the sticker in your drivers’ door jamb. Most vehicles also split the weight into front and rear weights. This information is also in the vehicle’s manual.

Make sure the jack you get can lift more than the higher of the two weights. For example, if you know you need 3100 pounds for the front (just over 1-1/2 tons), go for a floor jack that covers you for 2 or 2-1/2 tons. You don’t need to move up to the weight of a 3- or 4-ton unless you just like knowing you can lift a bigger vehicle.

A Short Interjection

One other thing—check the maximum height of your service jack. Some might only go up to 14″ or 15″. That works great on most cars, but get into trucks that have 20″ wheels and you won’t be able to lift it fully or you have to crawl under the vehicle to find a lower contact point.

Post time: Nov-18-2022